- Hyundai Motor’s Electric Global Modular Platform, or E-GMP, improves range, driving performance, and charging capabilities in BEVs

- Thanks to the flat structure of the platform, BEVs can benefit from enhanced interior proportions and driving performance

- IONIQ 5, the first battery-electric vehicle in the world to be built on E-GMP, incorporates new customer-centric features

Press material

-

Download

-

Images

Acting as the starting point for a new generation of Hyundai BEVs, the platform enables significant improvements in EV design, making them suitable for an even greater variety of lifestyles. Hyundai’s commitment to eco-mobility has pushed the company to set an ambitious goal of producing at least 11 exclusively BEV models within the next five years.

E-GMP is a dedicated platform for BEVs, meaning Hyundai did not borrow concepts from existing internal-combustion vehicle platforms but rather designed it specifically with battery-electric vehicles in mind. Without the need to accommodate a petrol or diesel engine, the platform enables unprecedented freedom in electric car design. Thanks to E-GMP, automotive designers can craft BEVs on various driving systems without compromising on interior spaciousness. For Hyundai customers, this means benefitting from more radical innovations.

Packed with benefits to simplify consumers’ lives

Hyundai BEVs built on E-GMP offer customers a range of benefits. One of the most significant is fast-charging capabilities. With a 350kW charger and 800V high-speed charging, the battery can charge from 10 to 80 per cent in just 18 minutes. This is already an improvement to the mainstream 400V charging, which can take anywhere between 30 minutes to an hour to charge the same amount. Five minutes of high-power charging alone can provide more than 100 kilometres of driving.

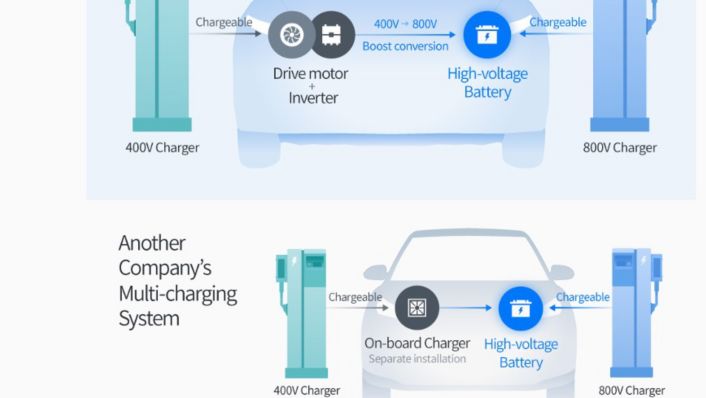

Integrated multi-charging possibilities

The E-GMP’s Power Electric (PE) system is the first system that supports multi-charging without manual components or adapters. On the other hand, vehicles that are not based on E-GMP require that a separate on-board charger be installed before a multi-charging system is possible, which, for the driver, means inconvenience and extra costs. Thanks to boost conversion, the rear motor and inverter enhance a 400V charge to 800V before it reaches the battery. This system consistently gives drivers access to 800V high-speed charging no matter the actual voltage of the charger.

Charger on wheels

With the hassle-free V2L (vehicle-to-load) function, any E-GMP-equipped BEV doubles as a high-capacity external power bank. Built-in bi-directional chargers can charge external battery-operated devices. To use the exterior V2L function, drivers only need to insert an adapter before charging. With a maximum power output of 3.68kVA, the V2L function meets all the needs of customers on the go – from smartphones and laptops to e-bikes and camping gear. Additionally, drivers can use their IONIQ 5 to charge other appliances and even other BEVs.

No more range anxiety

An improved range will also benefit customers. The standardised, high-capacity battery offers BEVs that are based on E-GMP better range. According to WLTP, IONIQ gives drivers up to 480 kilometres of range.

New platform for better performance

E-GMP also improves driving performance. The heavy battery is positioned between the axles, low in the centre of the platform, ensuring a low centre of gravity. Not only does this improve cornering, acceleration, and stability, it also enhances handling due to better weight distribution. The five-link rear suspension system supports longitudinal, lateral, and vertical forces from driving, optimising ride and handling performance. The integrated drive axle – a single structure that serves as the driveshaft and wheel bearing – delivers power from the motor to the wheels. Compared to when it is two separate parts, the integrated drive axle is 42 per cent stiffer and 10 per cent lighter, improving handling and ride quality.

Convenient battery maintenance

By standardising the battery cell and module into a single unit, E-GMP has simplified battery repairs. Now, damaged batteries no longer need to be switched out as a whole – only individual malfunctioning modules need to be fixed or replaced, reducing the cost of repairs for customers.

Designed to enhance the in-car experience

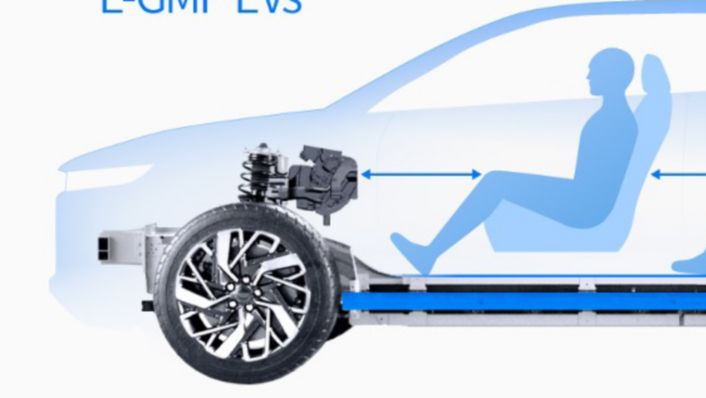

E-GMP has a liberating influence on the architecture of the BEVs that are built on it. Thanks to its elongated wheelbase and flat floor, interior spaces can be reimagined. In addition, a safety structure specific to E-GMP has been integrated.

Interiors with more space

E-GMP redefines the proportions of BEVs. Because they are powered by compact motors and batteries, BEVs based on E-GMP do not require bulky engines and driveshafts. They are designed with a longer wheelbase to accommodate the battery system, which is positioned low at the centre of the platform. The large, flat battery system creates a protrusion-free floor, improving the interior spaciousness of BEVs without compromising on versatility in driving systems.

For occupants, a long wheelbase and flat floor mean more legroom and therefore more travel comfort, especially on longer journeys. Additionally, occupants will have more freedom to move within the vehicle.

The front and rear seats as well as the sliding centre console can be arranged in a multitude of ways, matching the lifestyle needs of the customer. And with enhanced interior proportions, designers have more freedom to create innovative and roomy spaces. Instead of settling for conventional automotive design themes, the interior can be transformed into a new living space.

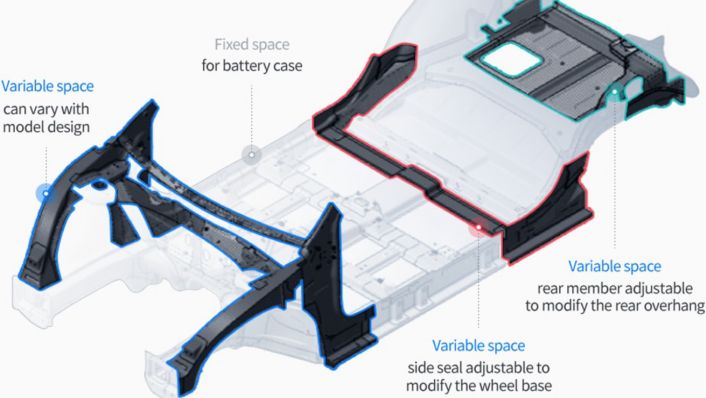

Interior based on a modular system

Hyundai engineers have created a flexible and modular platform, giving customers more vehicle options as it can serve as a basis for various types of applications and models. Flexible areas, such as side sill, rear member, and wheel and tire spaces, are variable spaces that are tailored to match vehicle characteristics, creating a new range of attractive model designs. Performance-dependent areas, such as the space for frontal shock absorption, front and rear suspensions, and the battery casing, however, are fixed firmly, meaning that they remain the same across all E-GMP-based models. These fixed spaces guarantee safer and smoother journeys as well as passenger and battery protection.

Reworked structural blueprint

Although E-GMP is compatible with both rear-wheel-drive (RWD) and all-wheel-drive (AWD) vehicles, it doesn’t incorporate the expected jutting floor structures. The absence of protrusions from a traditional ICE driveshaft enables the flat floor. E-GMP can accommodate the motor for RWD vehicles at the rear axle and, for AWD, another motor can simply be added to the front axle. This feature gives customers the freedom to switch between driving modes without compromising on interior spaciousness.

Without a bulky engine under the hood, the volume of the engine bay is drastically reduced for the compact motor. The front overhang has been shortened, the bonnet falls more sharply, and part of the HVAC system has been placed where an engine would have been, reducing dashboard volume and enabling a slim cockpit design. This dashboard design lets front-row occupants enjoy a more spacious and comfortable environment.

Strong structure for safer journeys

E-GMP also results in additional passenger safety. The steel structure has been optimised to absorb shock and distribute energy to keep both the battery and occupants safe. The multi-skeletal structure of the front collision frame absorbs collision impact energy. Near the bumper, the shock-absorbing rear collision frame serves to disperse collision impact.

The horizontal battery-penetrative mounting, made from ultra-high-strength steel plates, improves the stability of the battery-to-floor connection and protects the battery in case of a collision. The extruded aluminium reinforcements of the battery protection structure absorb impact energy in the event of a side collision.

IONIQ 5: the first battery-electric vehicle built on E-GMP

Hyundai has already launched its first production model to be built on E-GMP: IONIQ 5, the first BEV in the company’s new IONIQ line-up brand. IONIQ 5 is proof of the many tangible benefits E-GMP offers to customers.

Reimaged centre console

For one, the Universal Island centre console can be moved from front to back due to the lack of protrusions on the floor of the car. Thanks to the flat floor, it has enough space to slide back as far as 140mm. The sliding console grants passengers more flexibility of movement. Additionally, it makes it easier to enter and exit the car on either side when parked in a narrow spot. For rear row passengers, the Universal Island offers a 15W fast wireless phone charger and USB ports. Outperforming the static storage box, the Universal Island redefines the centre console with its ability to move and its enhanced functionality.

Enhanced-comfort seating

IONIQ 5’s front seats can be positioned in new ways due to the flat floor. The front seats are electrically adjustable. Reclining to relaxing angles, occupants can enjoy a comfortable feeling of weightlessness when seated. The front seats are also now 30 per cent thinner than seats in other Hyundai models, granting more legroom for those occupying the back row.

Additional storage space

The reduced engine bay leaves more space in the front of the vehicle for a second boot. Customers can enjoy up to 57 litres of additional storage space in the “frunk”, or front trunk. The feature comes in handy when travelling on long journeys, especially when extra luggage is needed.

Harnessing E-GMP’s potential

E-GMP will support a successful development and roll-out of future Hyundai vehicles. The platform will play a vital role in the company’s plan to introduce a total of 23 total BEVs within the next five years, including at least 11 dedicated BEV-only models such as IONIQ 5, 6, and 7. The company plans to sell more than one million BEVs worldwide by 2025. E-GMP marks a new landmark in the EV era, and the first model built on it, IONIQ 5, has been hailed a ‘game changer’ by the media. Launched earlier this year, IONIQ 5’s sustainable and innovative features redefine the electric mobility lifestyle.

Disclaimer: CO2 and emissions data for IONIQ 5

- Electricity consumption combined for the Hyundai IONIQ 5 58 kWh (19” alloy rims) with 2WD in kWh/100 km: 16.7; CO2 emissions combined in g/km: 0 (WLTP)

- Electricity consumption combined for the Hyundai IONIQ 5 58 kWh (19” alloy rims) with 4WD in kWh/100 km: 18.1; CO2 emissions combined in g/km: 0 (WLTP)

- Electricity consumption combined for the Hyundai IONIQ 5 72.6 kWh (19” alloy rims) with 2WD in kWh/100 km: 16.8; CO2 emissions combined in g/km: 0 (WLTP)

- Electricity consumption combined for the Hyundai IONIQ 5 72.6 kWh (20” alloy rims) with 2WD in kWh/100 km: 17.9; CO2 emissions combined in g/km: 0 (WLTP)

- Electricity consumption combined for the Hyundai IONIQ 5 72.6 kWh (19” alloy rims) with 4WD in kWh/100 km: 17.7; CO2 emissions combined in g/km: 0 (WLTP)

- Electricity consumption combined for the Hyundai IONIQ 5 72.6 kWh (20” alloy rims) with 4WD in kWh/100 km: 19.0; CO2 emissions combined in g/km: 0 (WLTP)